Just trying to keep our info updated and account active. It’s still difficult to use the forum and update our Fab Lab information properly - for instance, I can’t add staff, and it looks like we still can’t add events, of which we have many. Old photos on posts have disappeared and I considered removing the posts, but they still provide a nice look at our history, so I’ve left them in place with their missing photos.

In updating our equipment list, I also noticed that a bunch of inappropriate items now appear in the tool list, so hopefully, someone will check that out soon and weed out the spam.

Other than that, we’re happy to still be here and continue to thrive in our Uptown Tampa community. Here’s a New Year progress report:

Through FCDI’s Strategic Partnership Ecosystem, we bring together dozens of businesses and organizations, both for-profit and non-profit, to partner on programs and events at AMRoC Fab Lab that bring people of all ages together to learn, and succeed, in academic, professional and community-building experiences. Almost all our programs are free or very low cost, and all prioritize for University Area youth and families.

FCDI’s Equity in Entrepreneurship (EquinEnt) program has helped launch and revitalize over 35 small businesses since 2020 through entrepreneurship education, support including prototyping and rapid fabrication, and seed funding, distributing over $50,000 to early-stage entrepreneurs in the last four years. Community partners for this program include Truist, Hillsborough County Economic Development, the Temple Terrace Uptown Chamber of Commerce, Shane Smith of the Jim Moran Institute for Global Entrepreneurship, Ferguson Legal and eSmart Recycling.

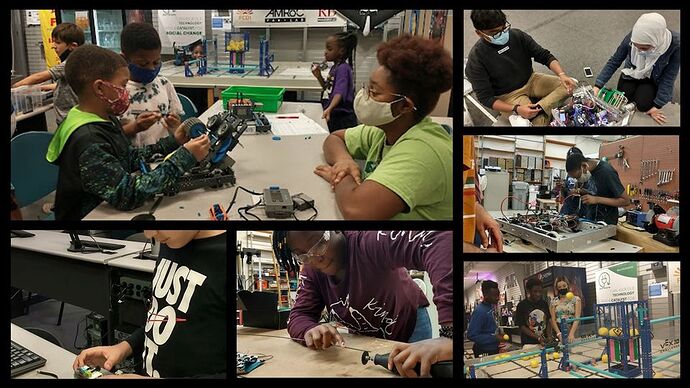

STEM Education for youth of all ages, through competitive robotics and drone programs, serves over 50 youth in-house and hundreds more, including many Hillsborough County Public Schools through year-round initiatives like field trips and camps, as well as FCDI’s ROBOTICON and Gulf Coast MakerCon. FCDI/AMRoC Fab Lab’s STEM partners include the Florida High Tech Corridor, SOFWERX, USF College of Engineering, USF College of Education, Florida Inventors Hall of Fame, Scoutlier, MITRE Corp, Visit Tampa Bay, Bits4Bots, Scientists, Inc. , Black Unicorn Education, City of Temple Terrace, Soaring City, and Rithm at Uptown among others – all organizations giving of their time, treasure and talent to help youth see the real world applications of the skills they’re learning through the competitive and project-based programming they experience at AMRoC Fab Lab.

FCDI’s Workforce skills development through internships, and collaborative partnerships with CareerSource, SOFWERX, University of South Florida (USF) Launch, which works with young adults on the autism spectrum, as well as USF Honors College, and USF Experiential Learning have helped place young adults from the area in trade education programs and academic pathways to help them on their way to better futures. FCDI has helped connect and place graduates and alumni of programs in well-paying careers and jobs around Tampa Bay and Florida, including at Mettler Toledo, Lockheed Martin, Amscot, and CAE, and has helped

Community Outreach programs are a signature way that FCDI communicates educational, workforce and skills development and other opportunities, providing showcases for the small businesses launched through the EquinEnt program, public robotics competitions and demos, and Gulf Coast MakerCon, an annual free public celebration of the community’s creative spirit.

FCDI is also active in community celebrations and events like CANDO’s Caribbean Heritage Festival, UACDC Partnership Coalition programs, Tampa Bay Community Network events, Uptown Chamber programs and events, Hillsborough County Economic Development’s Homebrew Hillsborough events, partners with WellFed Community and Homegrown Hillsborough, participates in USF events and programs like the USF Engineering Expo, Experiential Learning Fair, USF Connect events, and Soaring City, and often provides custom made awards and swag for various community organizations and programs. FCDI is also welcoming in making sure all community partners and organizations are invited to their open houses, events and programs, too.

Since FCDI opened AMRoC Fab Lab’s doors to the public in 2019, we have served as safe, welcoming, inclusive and accessible capacity-building community center, whose impact is measurable, documented and continues to grow.

You can keep up with our events, programs and progress at AMROCTampaBay.com and associated social media.

And if you’re ever in Tampa, FL, stop by to see us! We love it when sister Fab Labs visit and we love to get your news, too, so feel free to write me at Terri@ffcdi.org any time.

The Foundation for Community Driven Innovation is grateful to the Children’s Board of Hillsborough County for their recognition of AMRoC Fab Lab as the agency’s 2019 Social Enterprise Competition winner. Second place went to AMRoC’s wonderful friends and neighbors at the Caribbean American National Development Organization, Inc. for their Arts & Cafe program. We love that we could share in the honor together, bringing the best of science, technology and the arts to the University Area!

The Foundation for Community Driven Innovation is grateful to the Children’s Board of Hillsborough County for their recognition of AMRoC Fab Lab as the agency’s 2019 Social Enterprise Competition winner. Second place went to AMRoC’s wonderful friends and neighbors at the Caribbean American National Development Organization, Inc. for their Arts & Cafe program. We love that we could share in the honor together, bringing the best of science, technology and the arts to the University Area! value and purpose to do is important for our psyche or soul, as the case may be. Productivity matters, for so many reasons. That’s the whole point of AMRoC Fab Lab in the first place. But just because we can’t gather together in groups, doesn’t mean we can’t contribute to our community as individuals.

value and purpose to do is important for our psyche or soul, as the case may be. Productivity matters, for so many reasons. That’s the whole point of AMRoC Fab Lab in the first place. But just because we can’t gather together in groups, doesn’t mean we can’t contribute to our community as individuals. Like to sew? Help make medical

Like to sew? Help make medical

Almost all equipment at AMRoC Fab Lab has been donated, and dozens of volunteers contribute their time and expertise. But AMRoC tools and equipment require maintenance, and we’ve reached the point where newer equipment can be better to teach with and also has the added benefit of better safety features. There are also costs associated with all our programs, in addition to just keeping the lights on and paying the rent. Here are just a few examples of how your contributions can help:

Almost all equipment at AMRoC Fab Lab has been donated, and dozens of volunteers contribute their time and expertise. But AMRoC tools and equipment require maintenance, and we’ve reached the point where newer equipment can be better to teach with and also has the added benefit of better safety features. There are also costs associated with all our programs, in addition to just keeping the lights on and paying the rent. Here are just a few examples of how your contributions can help: If you’re interested in being a volunteer or mentor in any of our programs at AMRoC, visit

If you’re interested in being a volunteer or mentor in any of our programs at AMRoC, visit